Today, LeydenJar presents results from their Life Cycle Assessment (LCA) on pure silicon anode for next-generation Li-ion batteries.

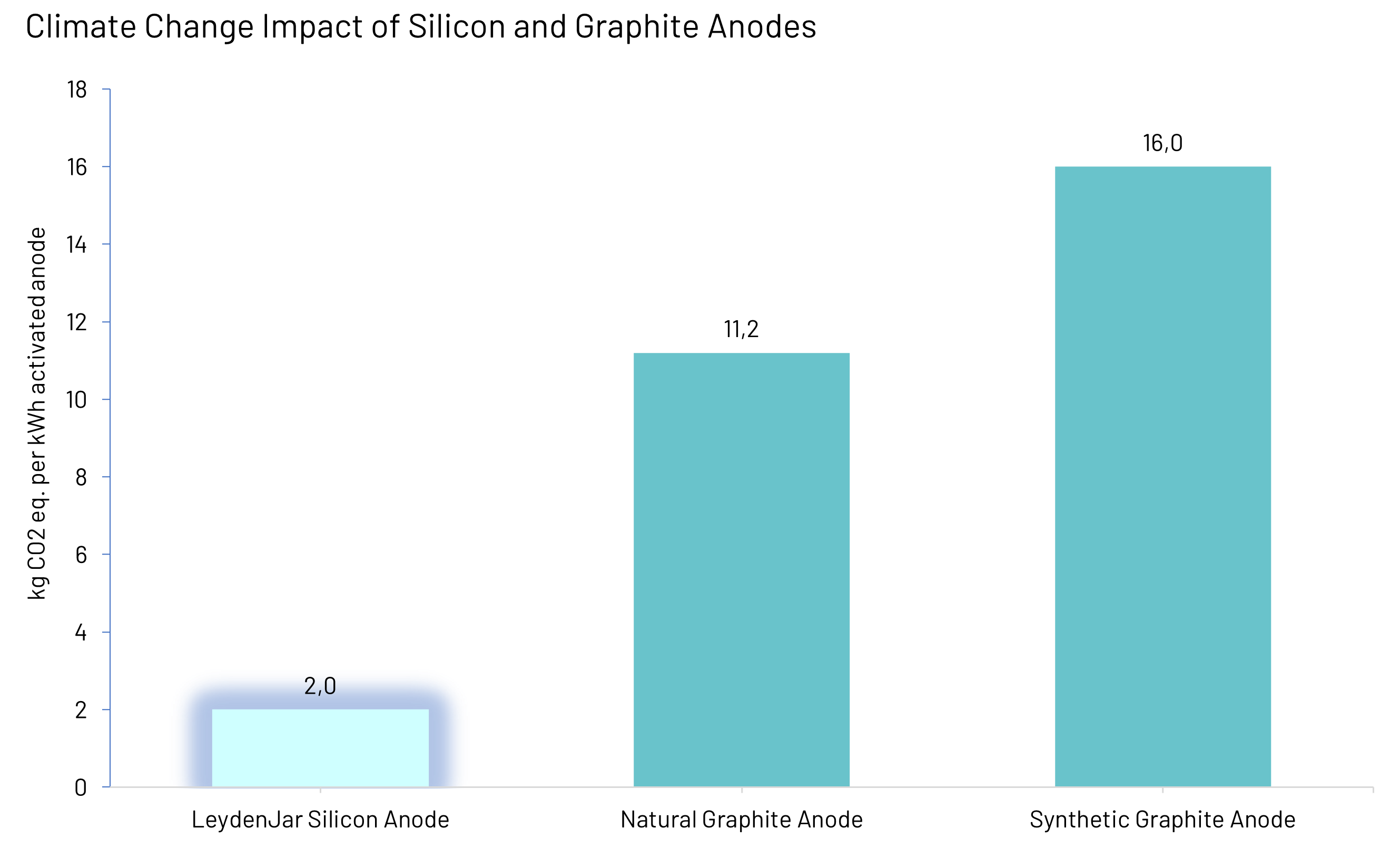

The study was conducted by Minviro, a renowned environmental consultancy specialized in life cycle assessment for mining and battery materials. It evaluated the environmental impact of producing LeydenJar pure silicon anode foil at scale, and compared the results to graphite anode production processes. The LCA shows a potential CO2-equivalent (CO2-e) emissions reduction of up to 85% for LeydenJar’s anodes compared to natural and synthetic graphite anodes. This underlines the major impact reduction capacity of LeydenJar’s pure silicon anode as the anode material of the future.

Differences in production process between graphite and LeydenJar silicon anodes

Although batteries are an essential building block for a fossil-free future, producing them still comes with environmental concerns. For example, processing and purifying the graphite used in today’s batteries into anode grade material uses large amounts of heat and energy, making it difficult to decarbonize. Additionally, mining graphite has a significant negative impact on the local environment in China, Mozambique, Madagascar and Brazil.

Silicon offers a promising path to fundamentally reduce the impact of anode manufacturing in two ways: silicon’s unique lithium-storing capabilities means less material is needed, and the simplified production process means less CO2-e is emitted per kg of material.

The LCA initiated by LeydenJar and performed by Minviro underpins this huge potential. For example, silane gas, the silicon anode precursor, can be produced using hydropower and metallurgical silicon from relatively abundant high-purity quartz feedstock. In addition, unlike the typical slurry coating process in graphite production, LeydenJar’s unique production process uses plasma to generate energy, does not require solvent or binder for adhesion, and skips the energy-intensive drying step completely. All this leads to a more energy-efficient process. Additionally, the single-step process deposits anode directly onto the current collector, which is 100% recycled copper, sustainably sourced from Western Europe.

The assessment, which took a cradle-to-gate approach (analyzing the impact from extraction to factory gate), closely evaluated five impact categories, including climate change impact, measured in CO2-e. Here, the production of silane gas and copper foil emerged as the main drivers of climate change impact. The CO2-e emissions of silane were mainly attributed to its production process. Copper foil production was found to be the second largest influencing factor. Such findings on LeydenJar’s upstream impact aids understanding and further reduction of emissions. Specifically, sourcing silane produced with 100% hydropower, continuing to source recycled copper, and using renewable energy for the electrode coating arose as three key improvement areas.

Results

The key outcome of the study is that LeydenJar’s pure silicon anode achieves a lower climate change impact than existing graphite anodes, emitting only 2.0 kg of CO2-e per kWh of activated anode. In contrast, synthetic graphite anodes emit up to 16.0 kg CO2-e per kWh; natural graphite anodes up to 11.2 kg CO2-e per kWh. The reduction of up to 85% pitches LeydenJar’s silicon anode as an essential building block for a low-emission battery ecosystem.

The study was independently verified by a board of battery experts, and included a sensitivity analysis to account for various possible routes towards mass production. These results showed that even in the worst-case scenarios, LeydenJar’s pure silicon anodes outperform current state-of-the-art graphite anodes, with a climate change impact of 1.8-2.2 and 6.1-6.5 kg CO2-e per kWh for ‘best-case’ and ‘worst-case’ respectively.

Silicon anodes for the electrification of our society

As the world moves towards widespread electrification of all transport modes, transport-related direct emissions are drastically reduced. What remains are emissions from the production phase of the vehicles themselves – and most notably from the battery. This study underscores that LeydenJar’s silicon anodes excel not only in terms of battery performance, but also in terms of environmentally conscious manufacturing for the impacts evaluated in this LCA study, thus reducing the climate change impact of battery material manufacturing, and paving the way for a zero-emission future.

Check out the video, where LeydenJar’s CEO Christian Rood, LeydenJar’s Environmental Analyst Elizabeth Couves and Minviro Sustainability Consultant Lydia Bridges explain the details of the LCA.