Applications for Pure Silicon Anodes:

Transform wearables, smart devices , and e-mobility with smaller cells that pack the same amount of energy.

APPLICATIONS

Pure Silicon Anodes Transform Next-Generation Li-ion Batteries

Even after decades of improvement, a device’s form factor is still inextricably bound to the shape of its battery. From small personal devices such as smartphones and smartwatches to e-mobility solutions like drones and EVs, the dimensions of the battery often dictate the dimensions of the product. What if we can break this link?

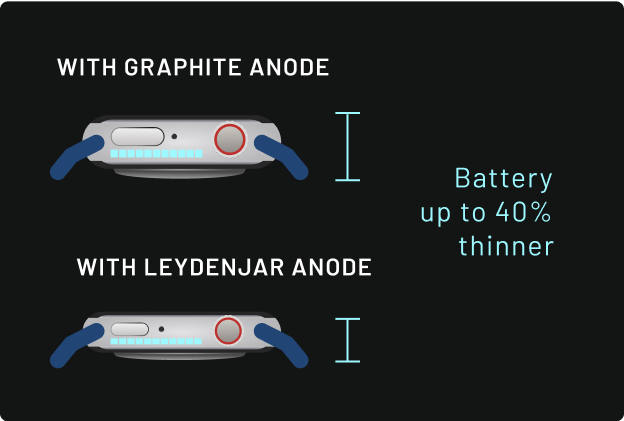

Imagine if your device could use a battery that’s up to 40% smaller or with energy density increased by 50%. Imagine if you could avoid severe tradeoffs in the form of energy density, cycle life, or (dis)charge rate. You’d be able to incorporate more intelligence and memory, better ergonomics, or a more eye-catching design.

Wearables

Although wearable devices exhibited astonishing growth during the first part of the decade, the pace of technological innovation has slowed. Smartwatches and earbuds have achieved widespread adoption, but other types of devices such as smart glasses, smart rings, and VR headsets have yet to catch up. What’s the reason for this slower pace of growth?

The answer is that batteries for wearable devices are still too large and too heavy. Right now, users might find that smart glasses aren’t ergonomical for all-day use – but if you shrink the battery to make them more comfortable, they won’t last all day on a single charge.

What if you could make smart glasses that are comfortable enough to wear all day, with battery life to match? What if you made a smartwatch that was small enough to compete in terms of aesthetics while retaining must-haves like fitness tracking? What if your earbuds had better sound quality because of increased room for audio hardware?

With pure silicon anodes from LeydenJar, you can shrink the size of the battery inside your wearable devices by up to 40% without any decrease in performance or lifespan. Using this innovation, you can create more lightweight and comfortable wearable devices – or even design something completely new.

Flexible Wearables for Added Comfort

LeydenJar offers a fantastic advantage for wearables manufacturers – reducing the size of a smartwatch battery by up to 40% – but that’s not the only benefit.

Most Li-ion cells must be rigid, but pure silicon anodes can bend without breaking. This means that you can add batteries to products in areas where they can conform to a user’s skin or clothing, creating a more comfortable experience and even more design flexibility.

Frequently asked questions

Everything you need to know

Can LeydenJar’s silicon anodes be integrated into Lithium-ion batteries?

Yes! Pure silicon anodes from LeydenJar can be integrated with almost any lithium-ion battery that exists today. Our anode works with off-the-shelf cathodes and electrolytes. They’re also compatible with current cell assembly lines and suitable for mass production. The anode foil can feed directly into a cell manufacturer’s cutting and stacking process.

What are the advantages of pure silicon anodes?

Pure silicon anodes can store the same amount of energy using much thinner layers. This results in increased energy density, improved charging rates, and decreased material usage compared to graphite anodes.

Can silicon anodes be easily and cost effective be implemented into existing battery production processes?

Silicon anodes from LeydenJar are fully compatible with current battery production processes. In addition, moving away from graphite anodes to LeydenJar silicon anodes simplifies existing production processes by eliminating wet slurry coating and replacing it with a plasma enhanced chemical vapor deposition (PECVD) process. This dry production process is more scalable, consumes less energy, and uses fewer scarce material inputs.

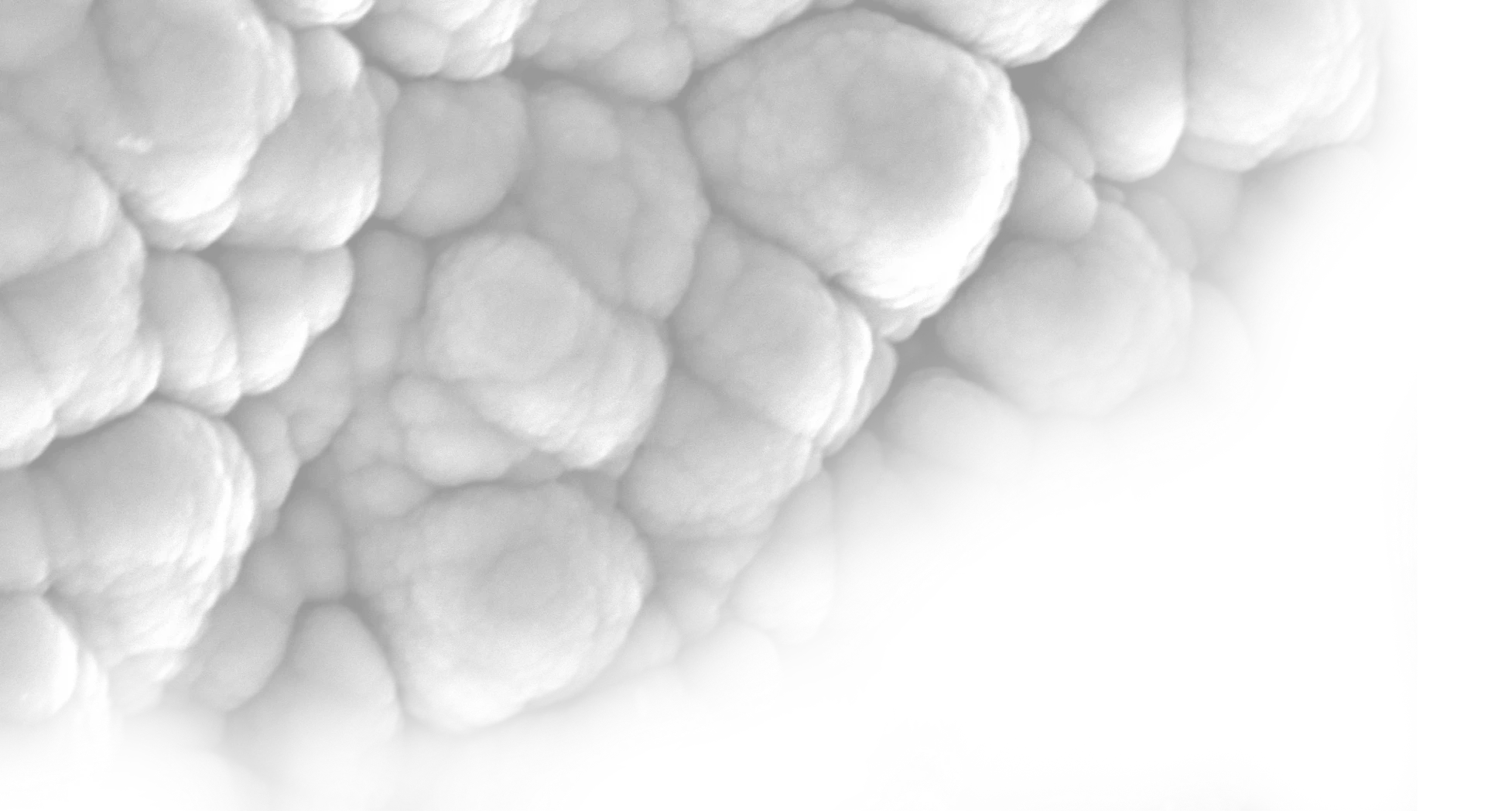

Are there challenges with silicon anodes?

Silicon swells while charging, which normally prevents silicon from being used in batteries. LeydenJar’s silicon anodes are produced with a PECVD process that forms porous columns on the copper substrate. This limits silicon swelling and makes durable, high-performing silicon anodes a reality.

Are LeydenJar silicon anodes practical for long-term use?

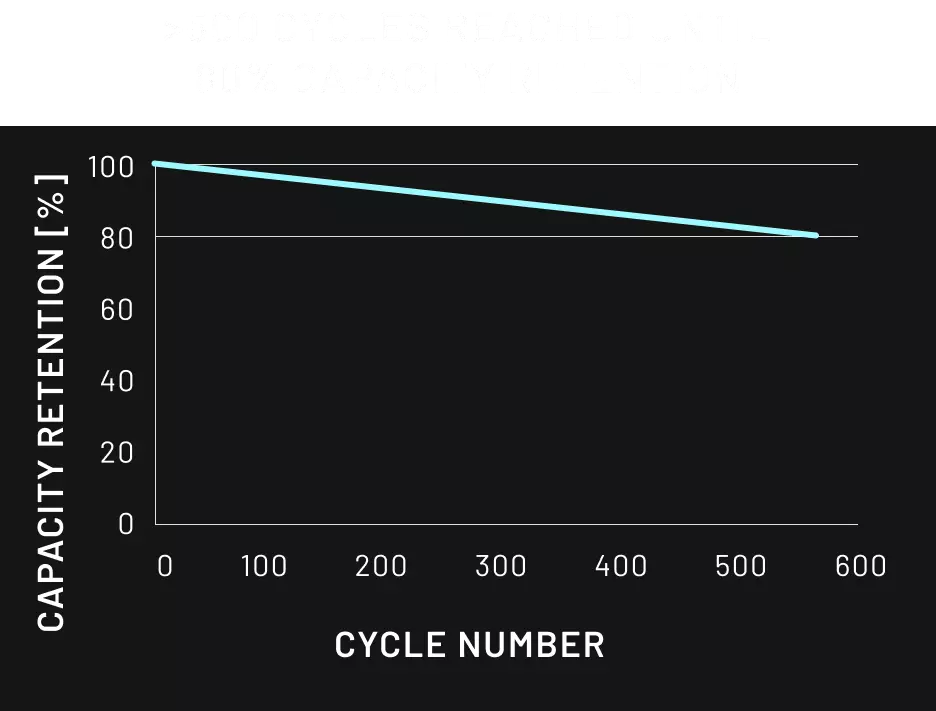

LeydenJar’s silicon anodes last longer than other silicon anode designs. They are designed with an improved nanostructure that limits swelling and prevents delamination. This eliminates the main failure mechanisms of silicon anodes and increases cycle life to 500 cycles at 80% capacity retention and 700 cycles at 70% capacity retention.

Are silicon anodes compatible with off the shelf cathodes?

Yes. LeydenJar’s silicon anodes have been tested with NMC, LFP, and LCO cathodes and have been proven to work with all of them. They also work with a wide variety of electrolytes and cell designs, making them a perfect fit for almost any type of battery cell.

What is the energy density of batteries with LeydenJar’s pure silicon anodes?

1350 Wh/L or 390 Wh/kg (nominal stack level energy density).

Can the silicon based battery be utilized in every application?

Yes. Silicon anodes can produce benefits in any application where Li-ion batteries are currently used. They currently provide the most value in applications that require high energy density. These include wearables, smart devices, and e-mobility.

Are the LeydenJar anodes made of 100% silicon?

Yes, 100% — no graphite, no binders, and no additives. We create the only pure silicon anode that can be used in mobile device applications without clamping pressure.

How do I get these silicon anodes in my application?

Fill out our contact form and we’ll get started producing a battery that can fit your needs!